Industrial Quality Control

Fast, accurate inspection of surfaces, parts, and assemblies to catch defects before they reach the customer.

Smart G-Scope streamlines visual inspection in industrial environments thanks to its plug-and-play USB connection and fast autofocus.

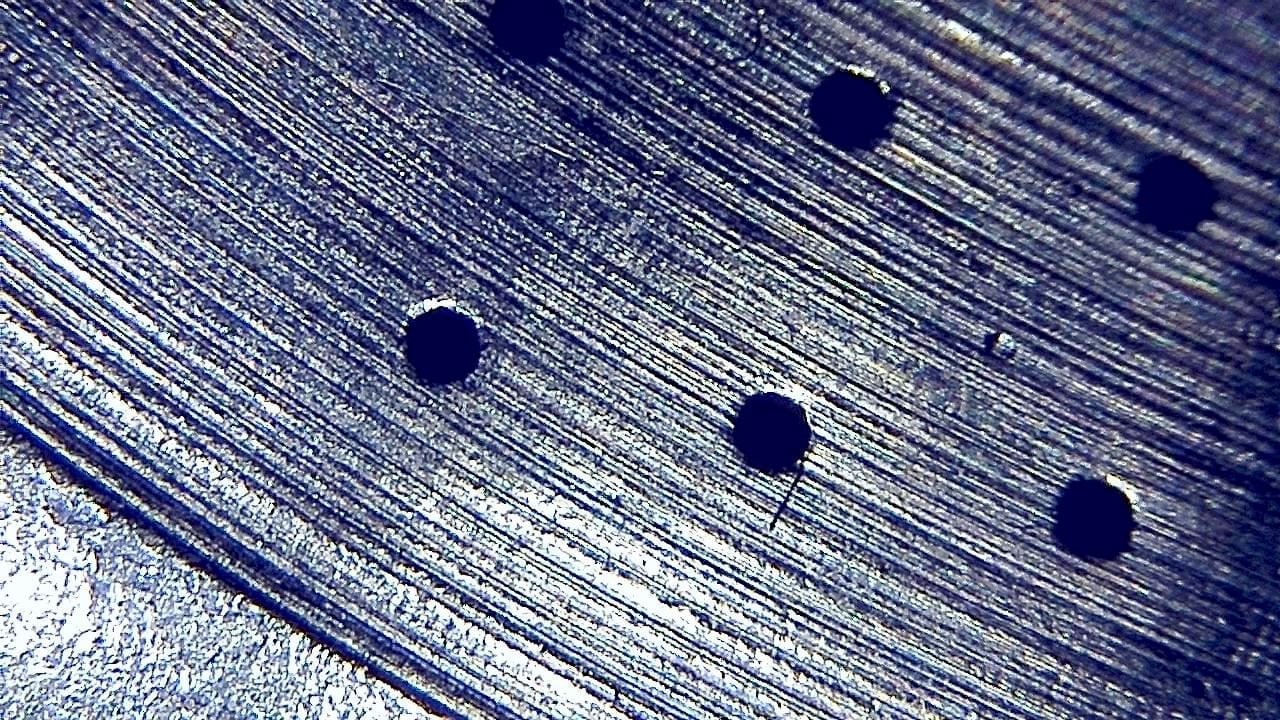

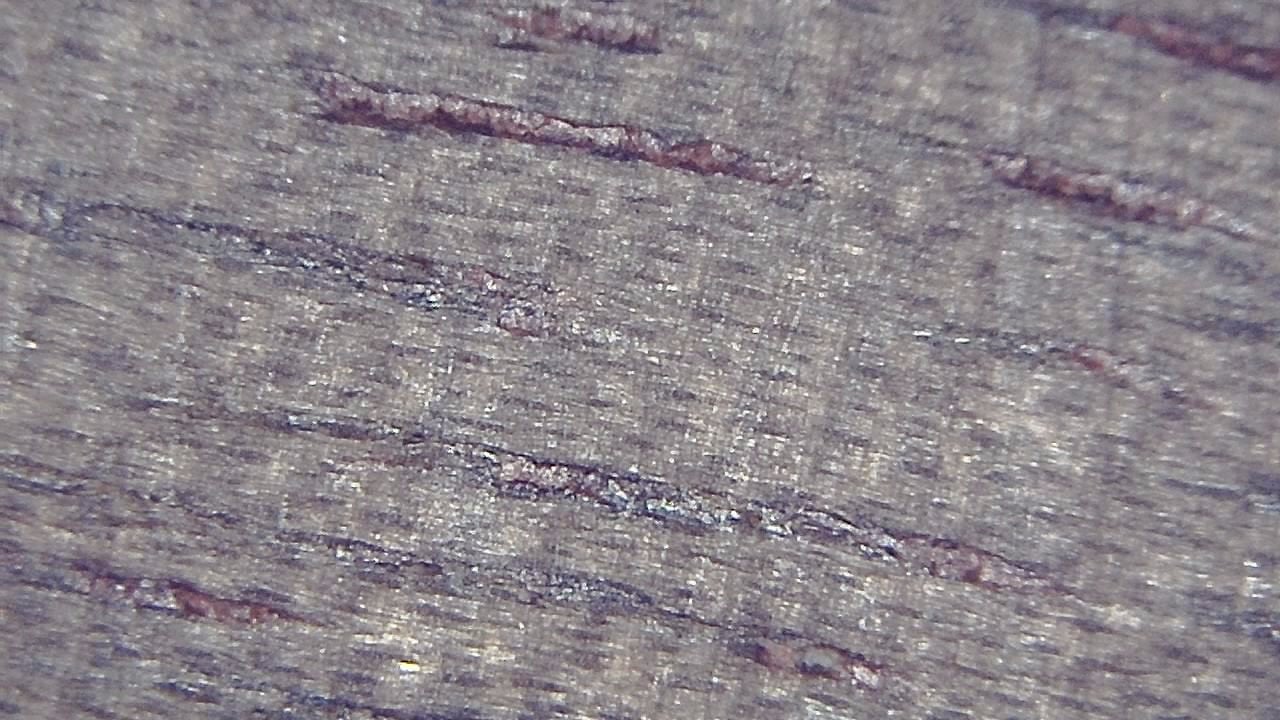

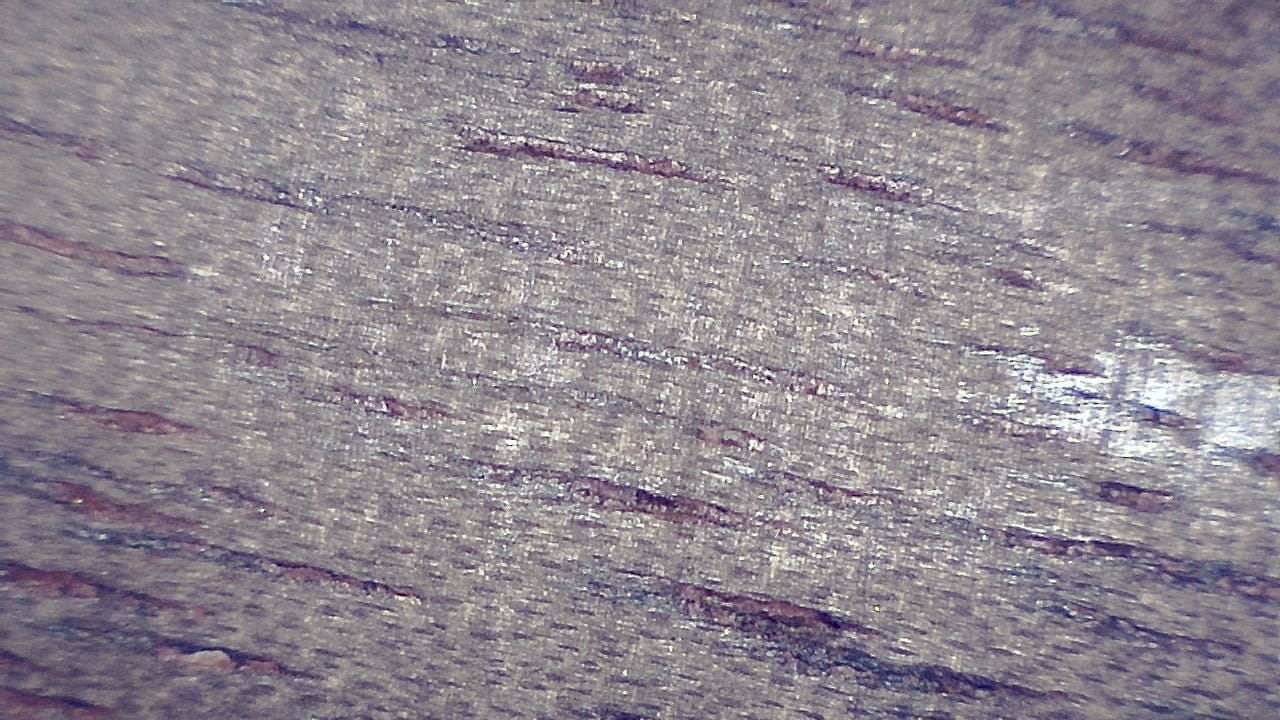

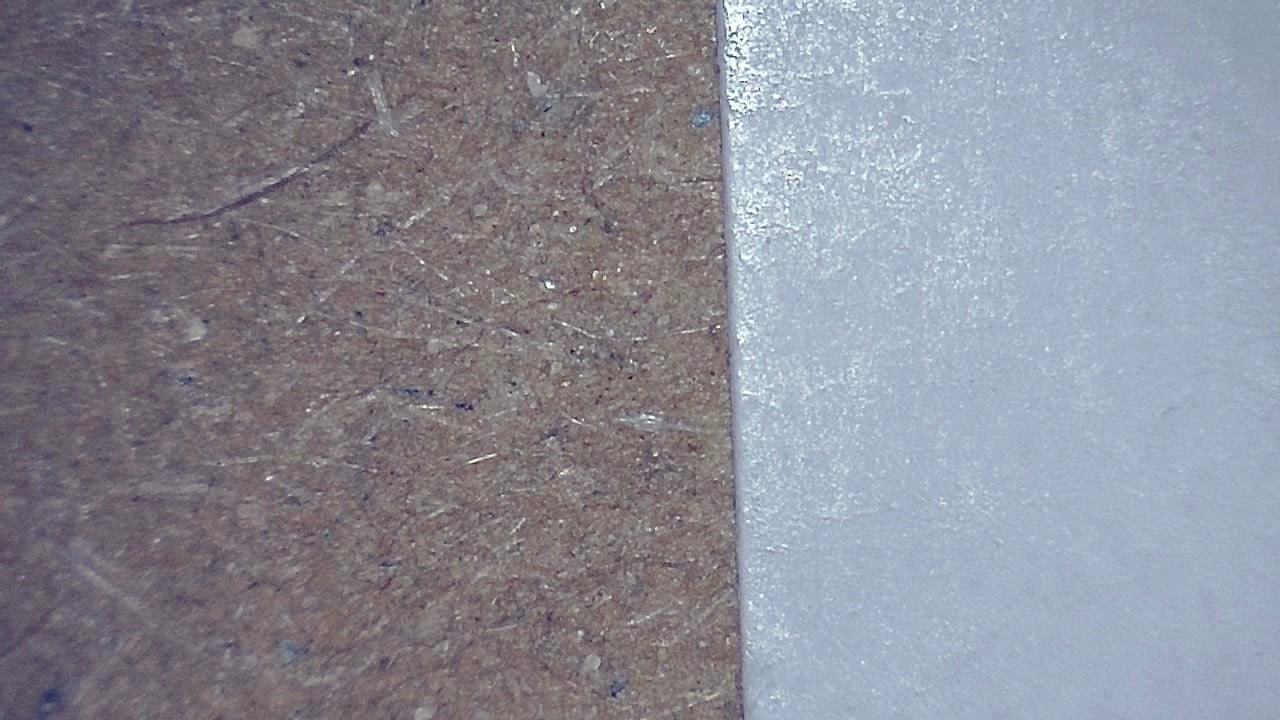

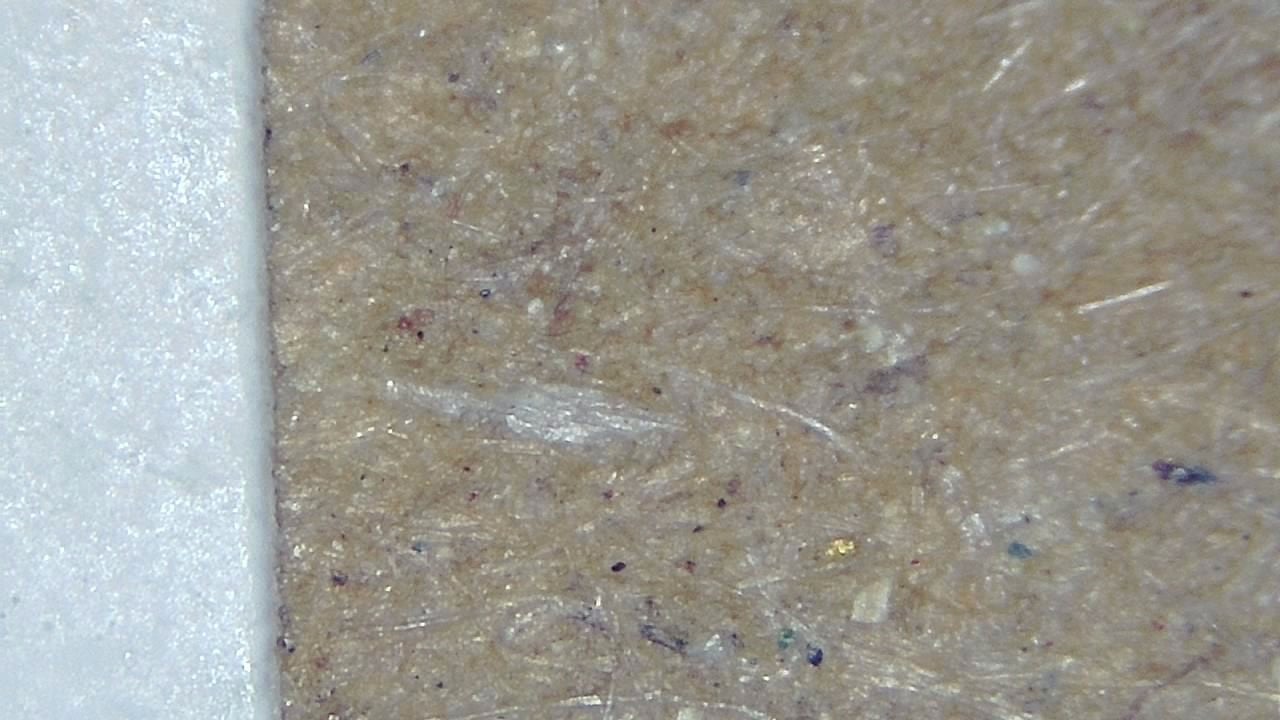

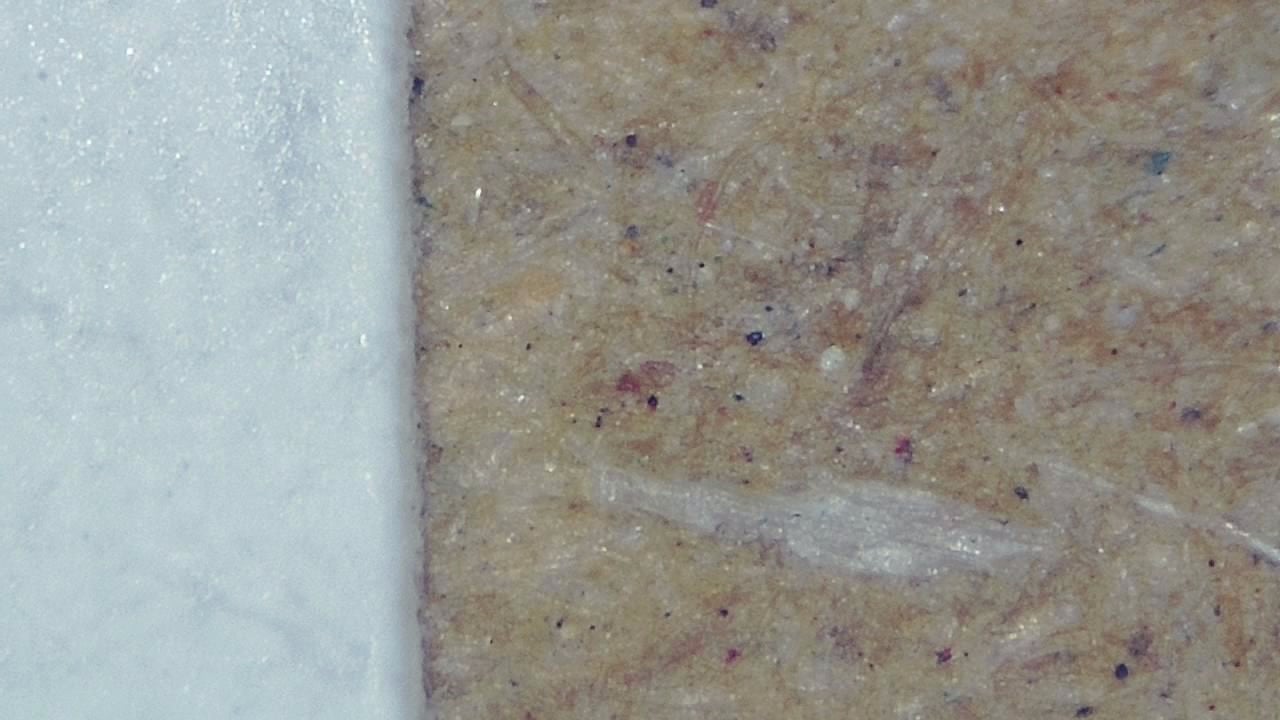

It is especially useful for spotting surface defects (micro-cracks, burrs, scratches), contamination, or finishing issues on machined parts, plastics, metals, and coatings.

It enables you to document evidence (photo/video) and share it with production or QA teams for traceability and continuous improvement.

Key benefits

- Early defect detection to reduce returns and rework

- Instant documentation with photo/video capture

- More consistent inspection with a stand for repeatability

- Compact device that can be easily moved between production lines

Practical examples

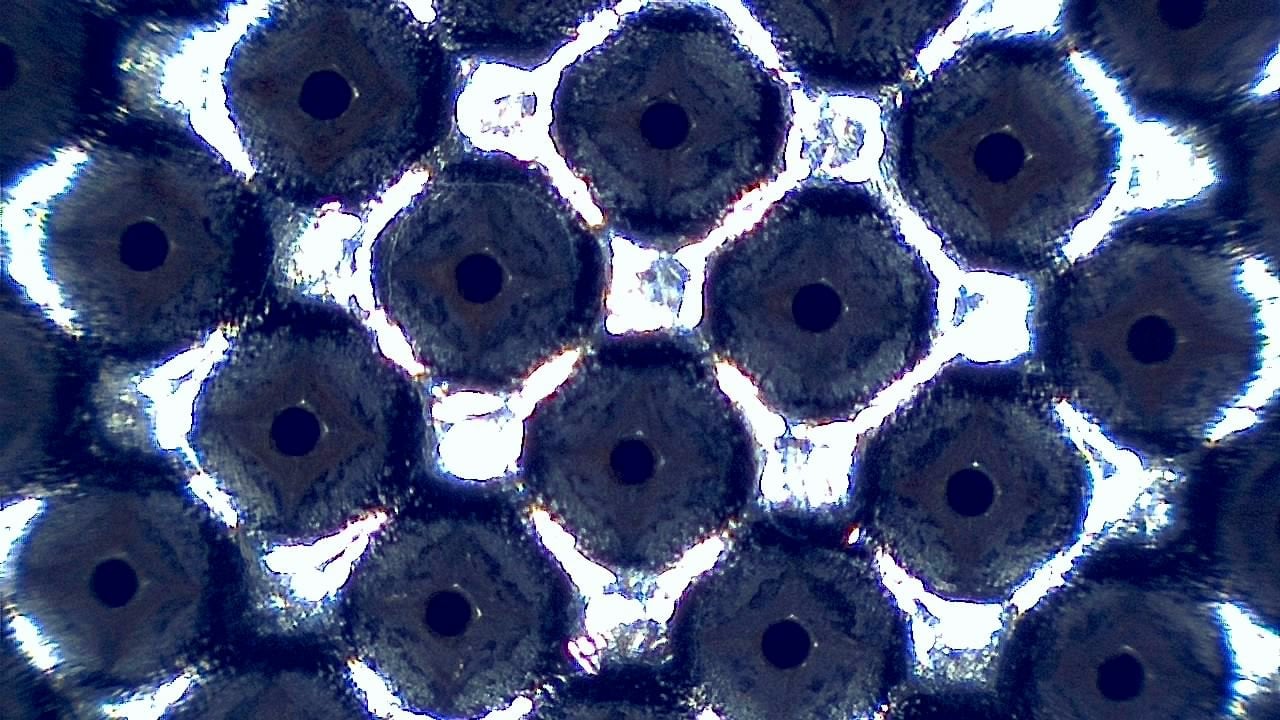

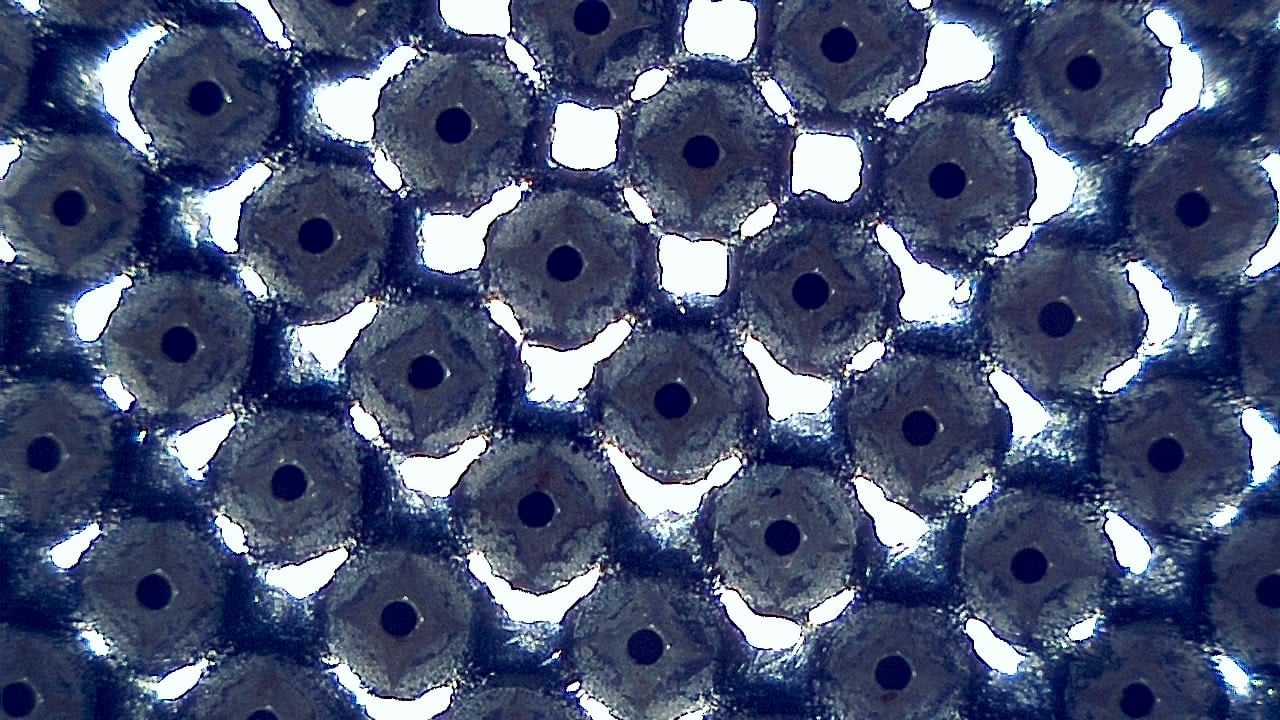

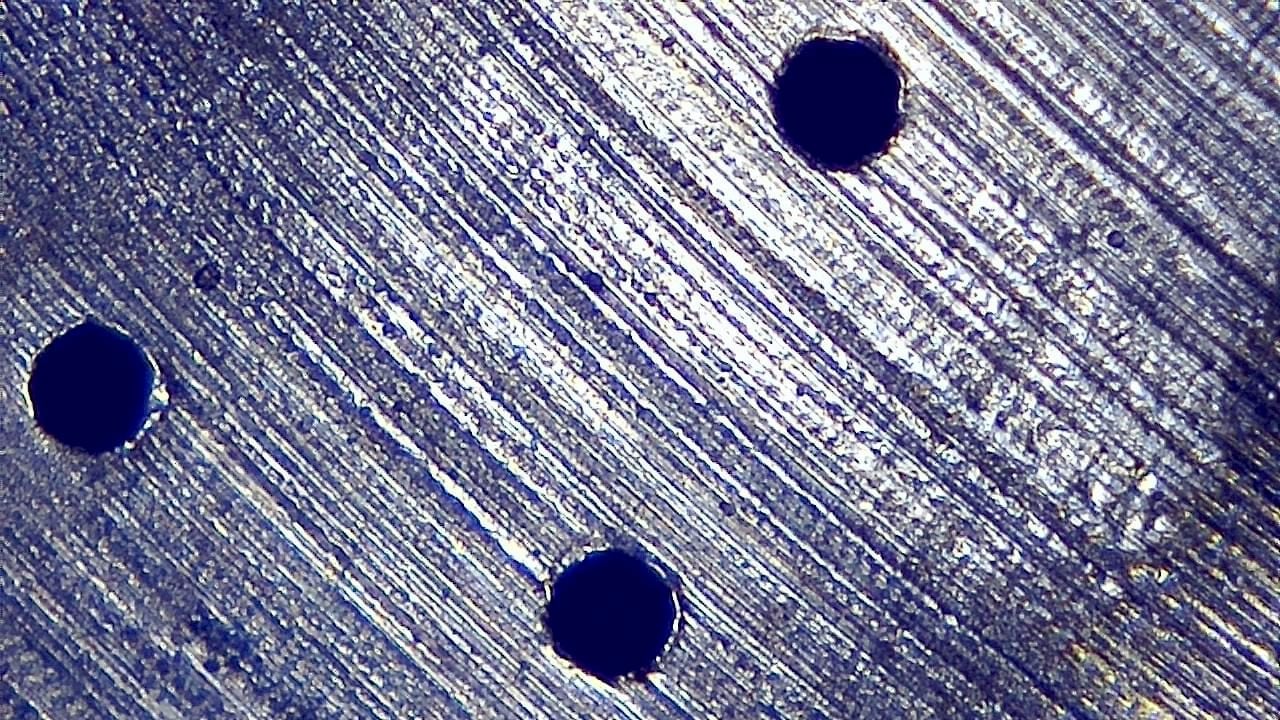

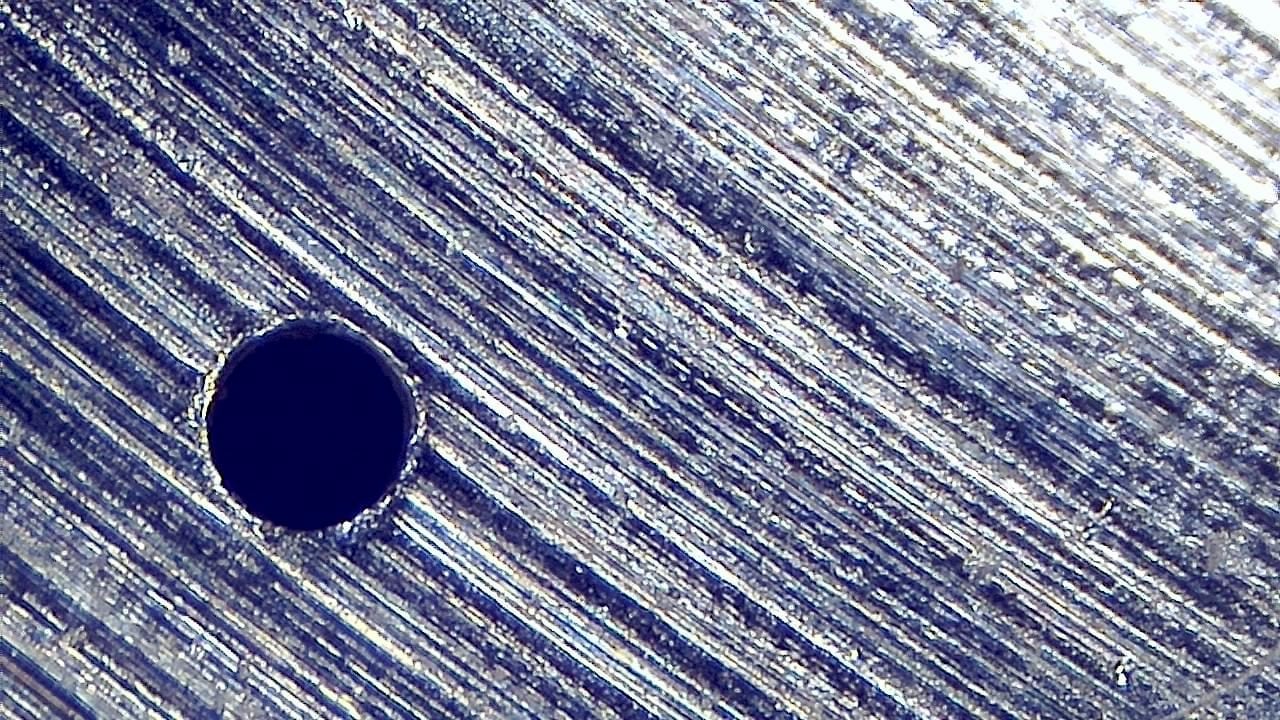

Inspection of machined parts

Check for micro-burrs, tool marks, or finishing defects on metal parts before final assembly.

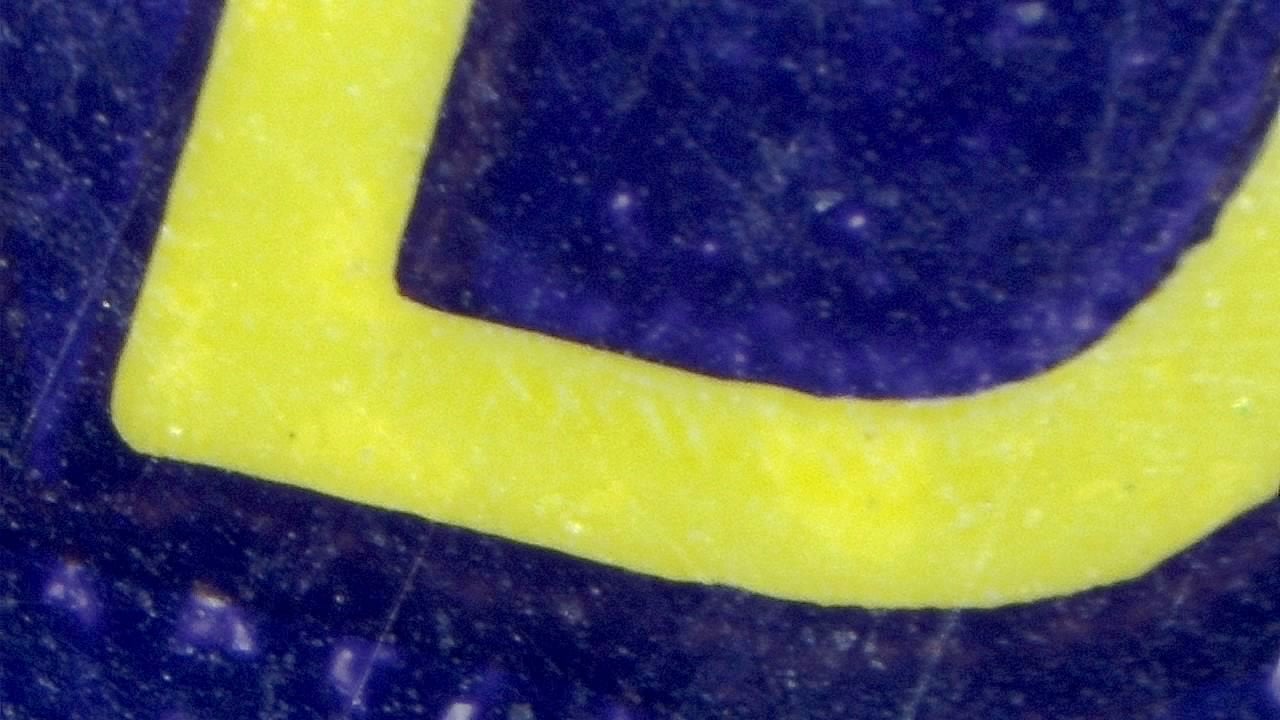

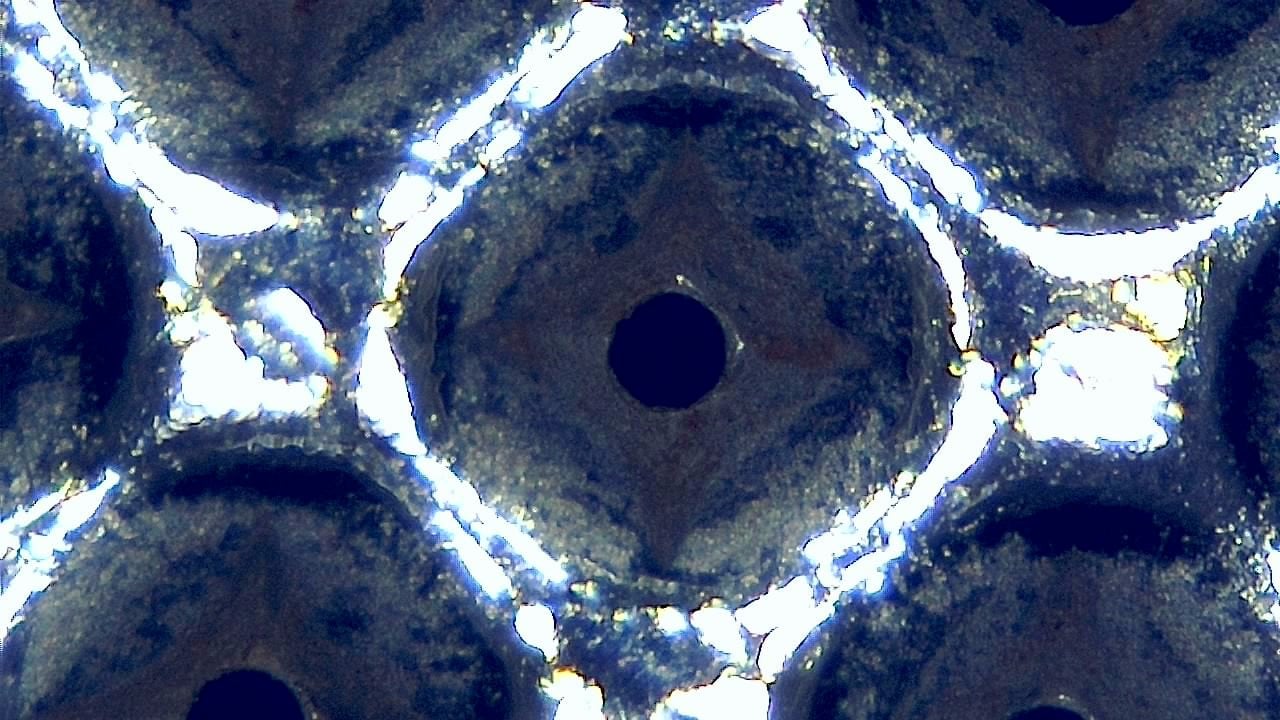

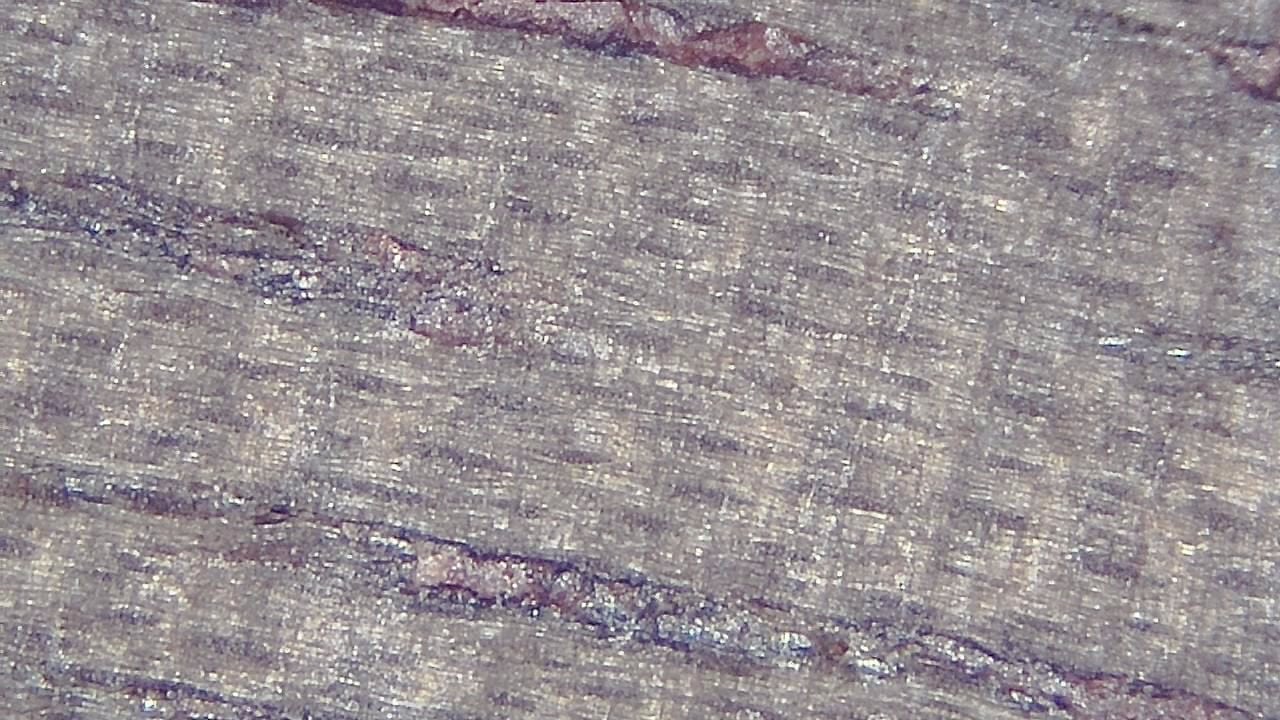

Surface and coating control

Detect pores, fine cracks, or lack of uniformity in paints, varnishes, or technical coatings.

Assembly validation

Verify alignment and the condition of small parts in assemblies where the naked eye isn’t enough.

Limitations & best practices

- It does not replace certified metrology measurements (micrometers / calibrated machine vision) when standards-grade tolerances are required.

- On highly reflective surfaces, you may need to adjust lighting and angle to reduce glare.

Interested in this use case?

Buy Smart G-Scope

Get the right kit for this application. Secure checkout and fast shipping.

Need help choosing? Tell us your workflow and we’ll recommend the best setup.

Related use cases

Electronics/PCB

Inspection of solder joints, components, and defects on printed circuit boards.

3D Printing

Surface quality control, layer defect detection, and material assessment for 3D-printed parts.

Jewelry/Watchmaking

Inspection of gemstones, settings, watch mechanisms, fine metalwork, and collectible coins for authentication and condition assessment.

Printing

Evaluate halftones, color registration, and print defects in detail for quality control in printing and packaging.

Food

Supports visual quality control of foods and raw materials through fast inspection and documentation.

Cosmetics

Visual inspection of textures, particles, and impurities for quality control and product development.

Textiles

Detect defects in fibers, weaves, and finishes for textile quality control.