Food Industry

Supports visual quality control of foods and raw materials through fast inspection and documentation.

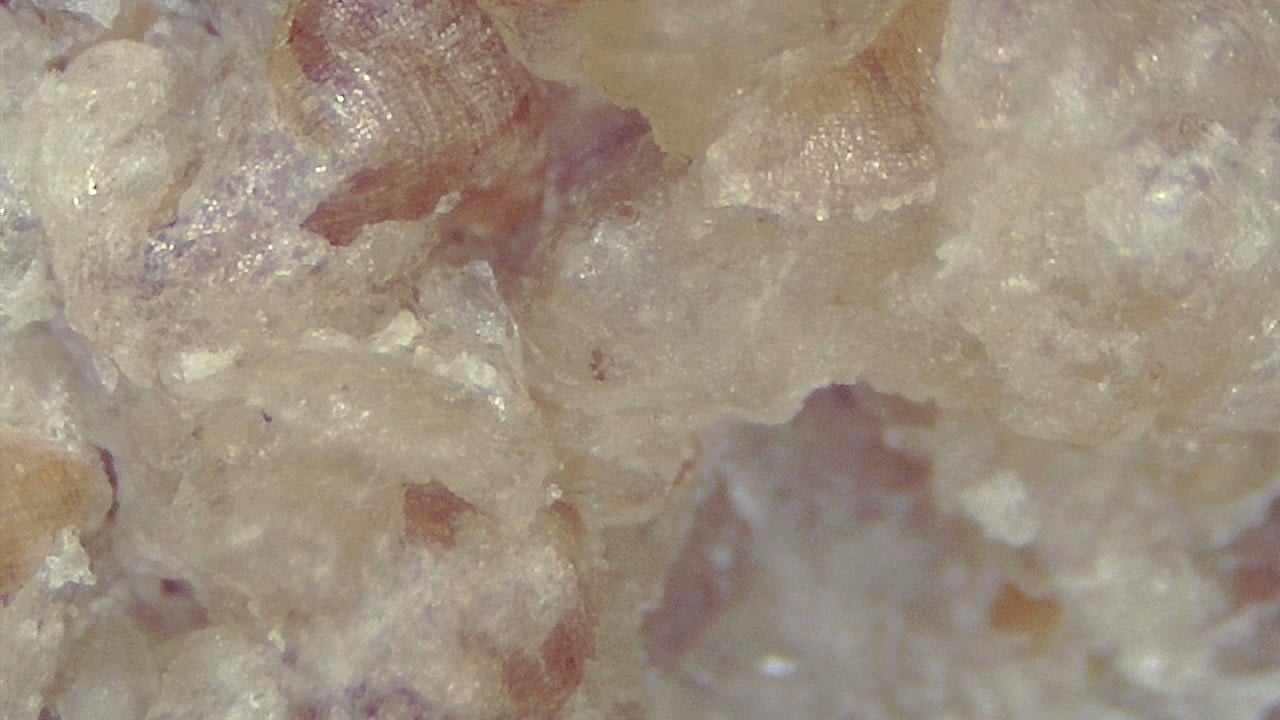

Smart G-Scope can be used as a supporting tool for visual inspection of raw materials and products, helping detect surface defects, visible contaminants, or irregularities.

It is useful for training, internal audits, and documenting production incidents.

It enables capturing visual evidence for quality reports and traceability.

Key benefits

- Fast incident documentation

- Supports visual QC processes

- Compact and easy to deploy

- Useful for training and internal procedures

Practical examples

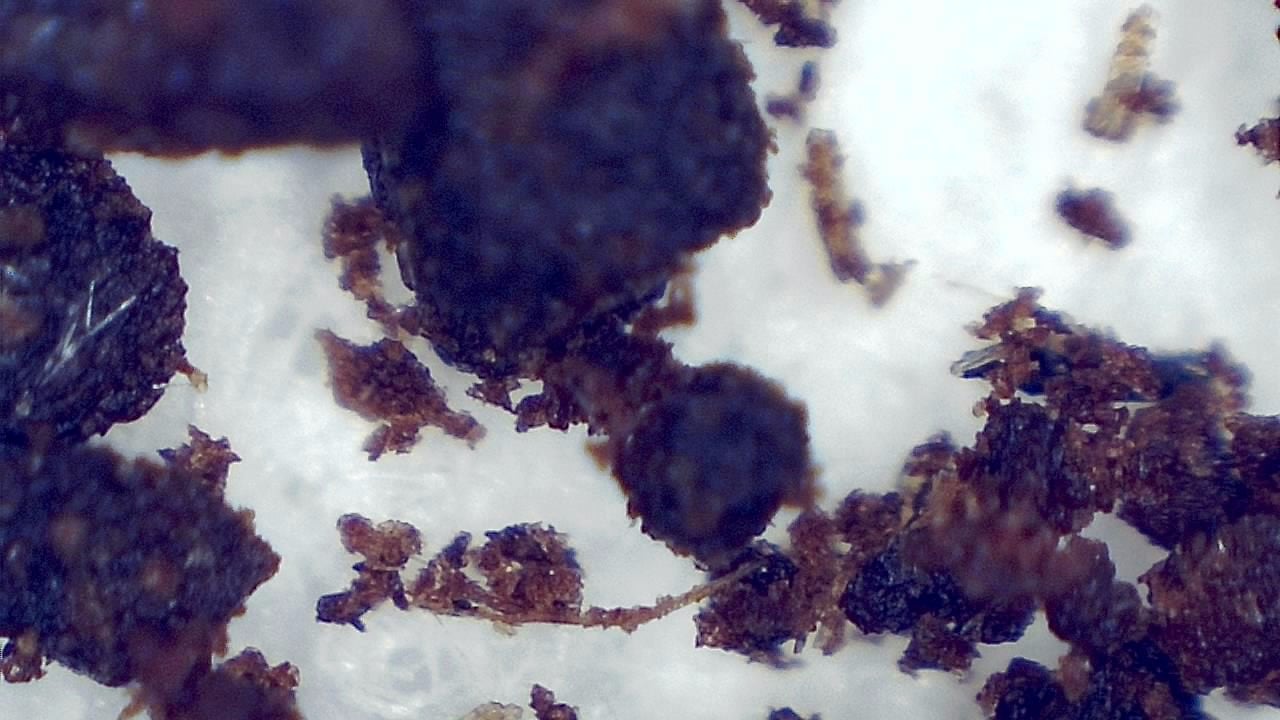

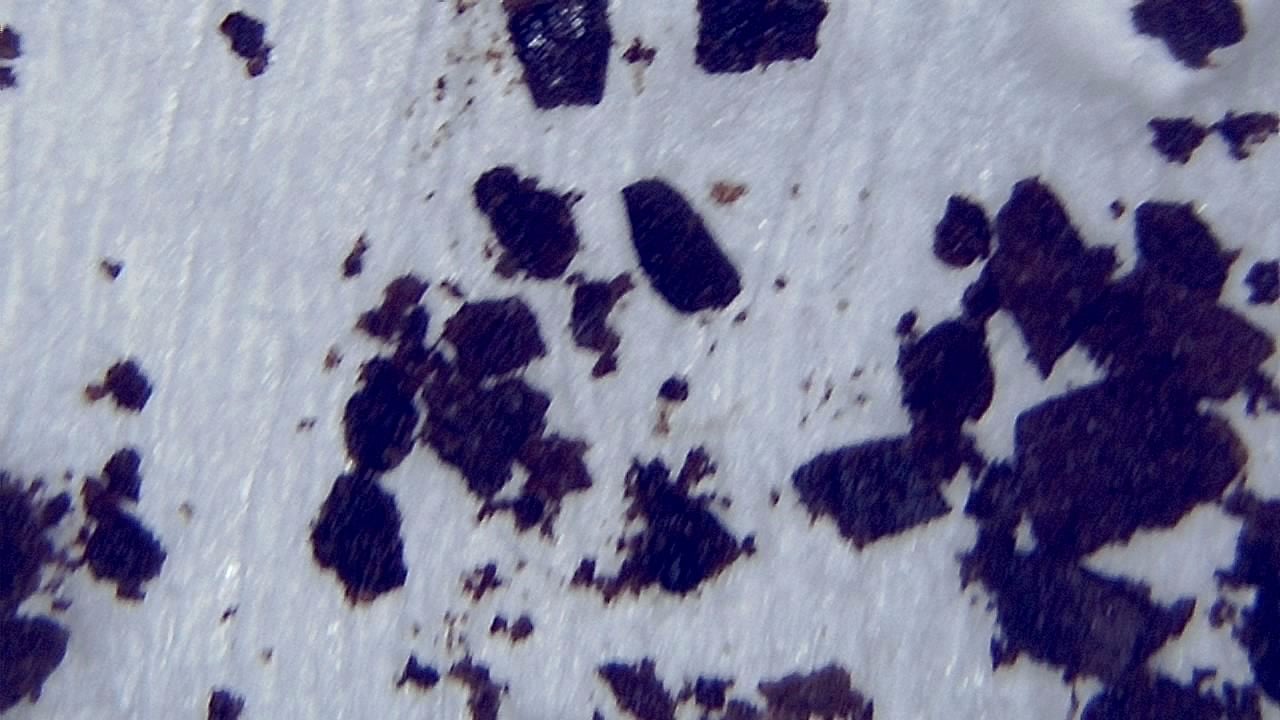

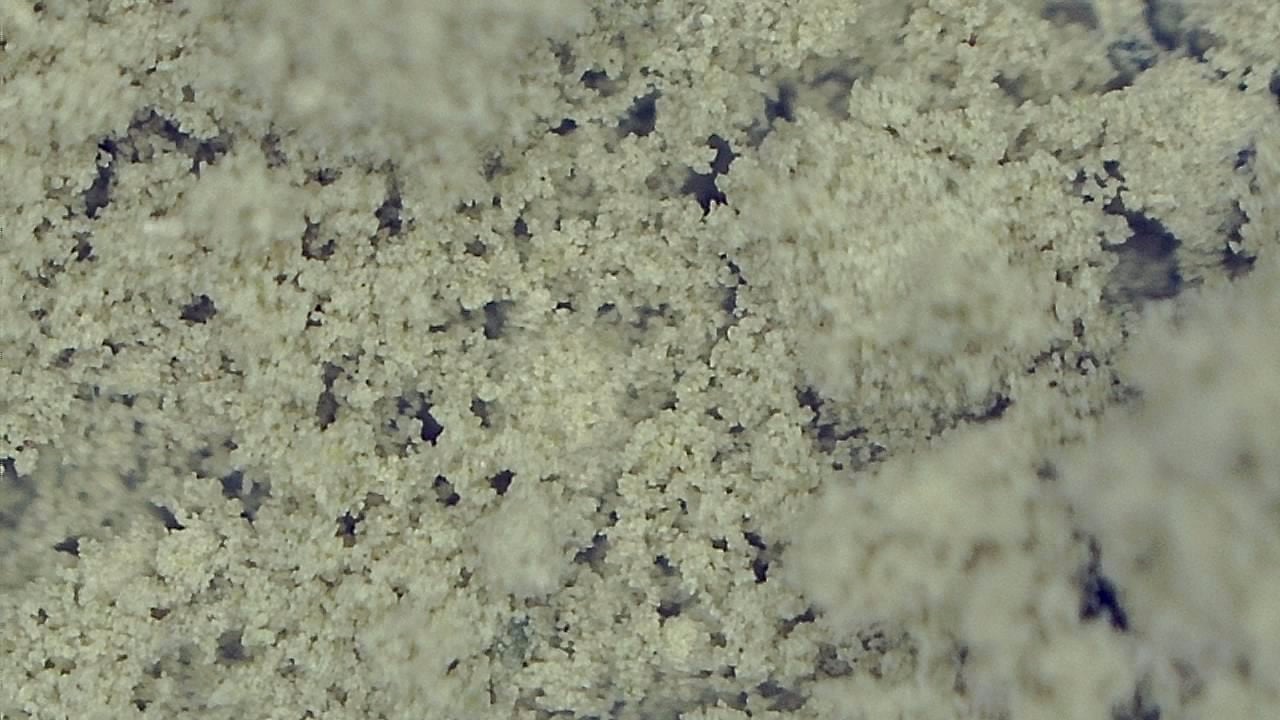

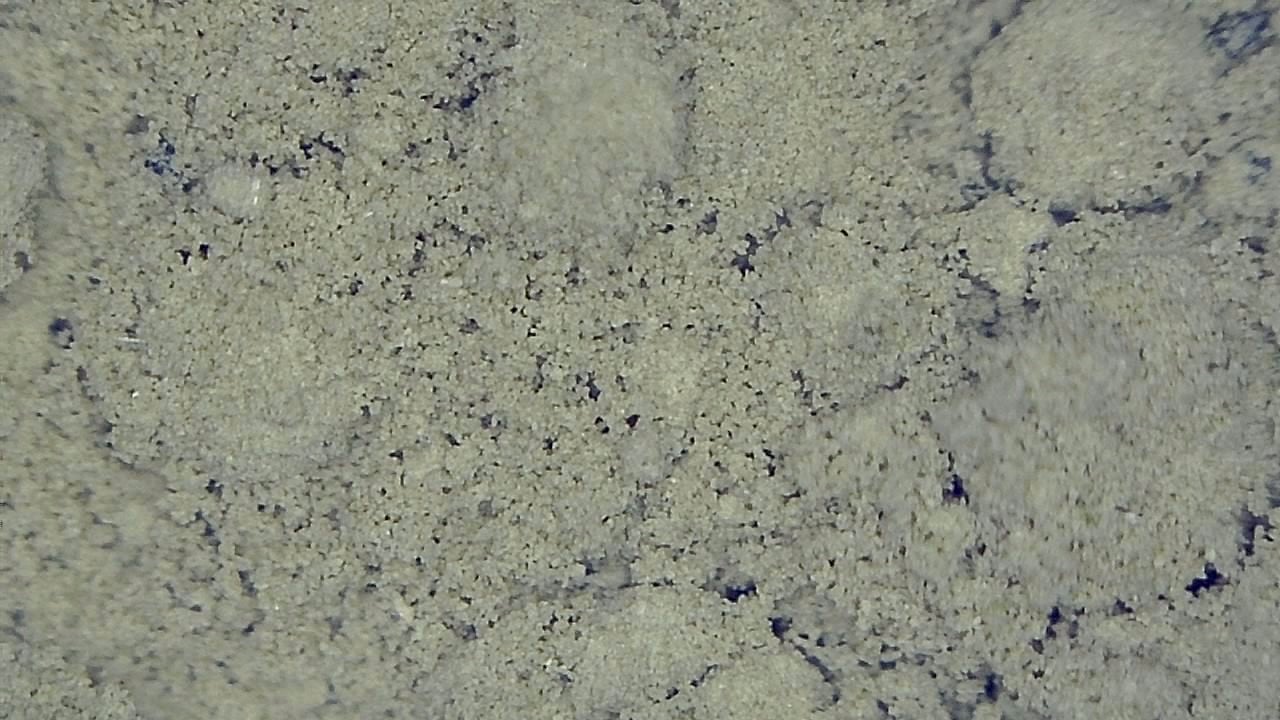

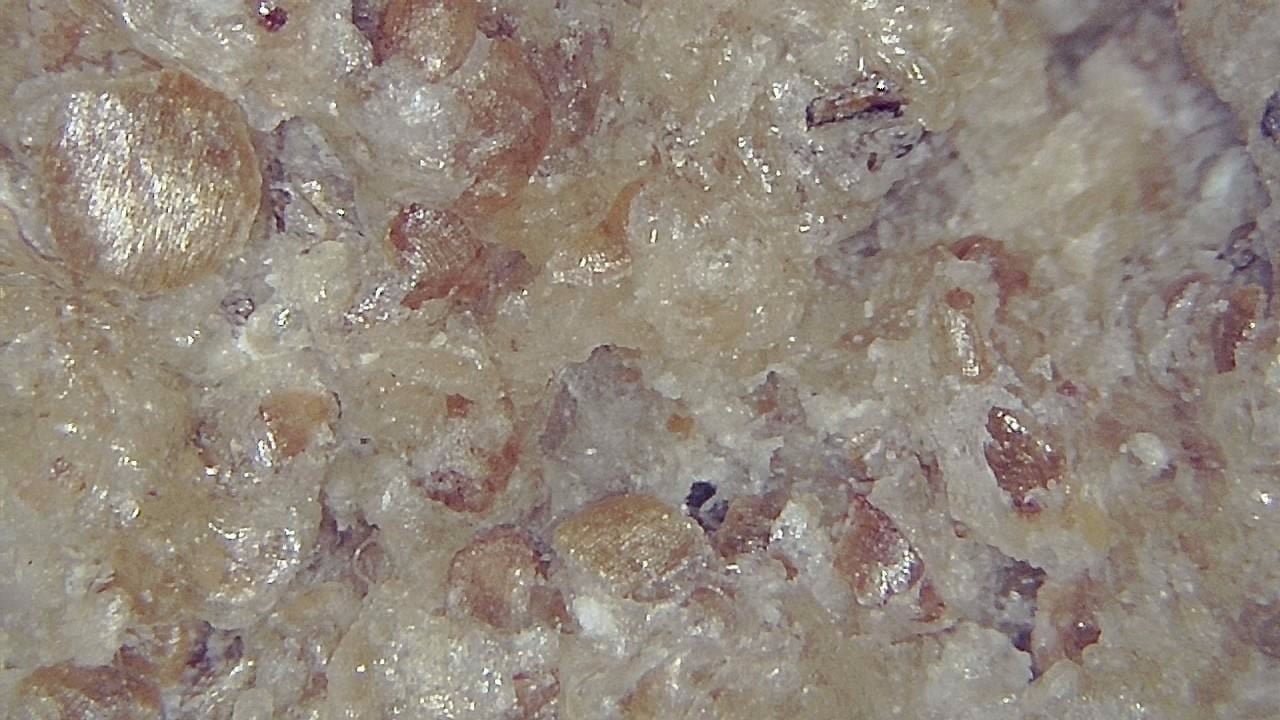

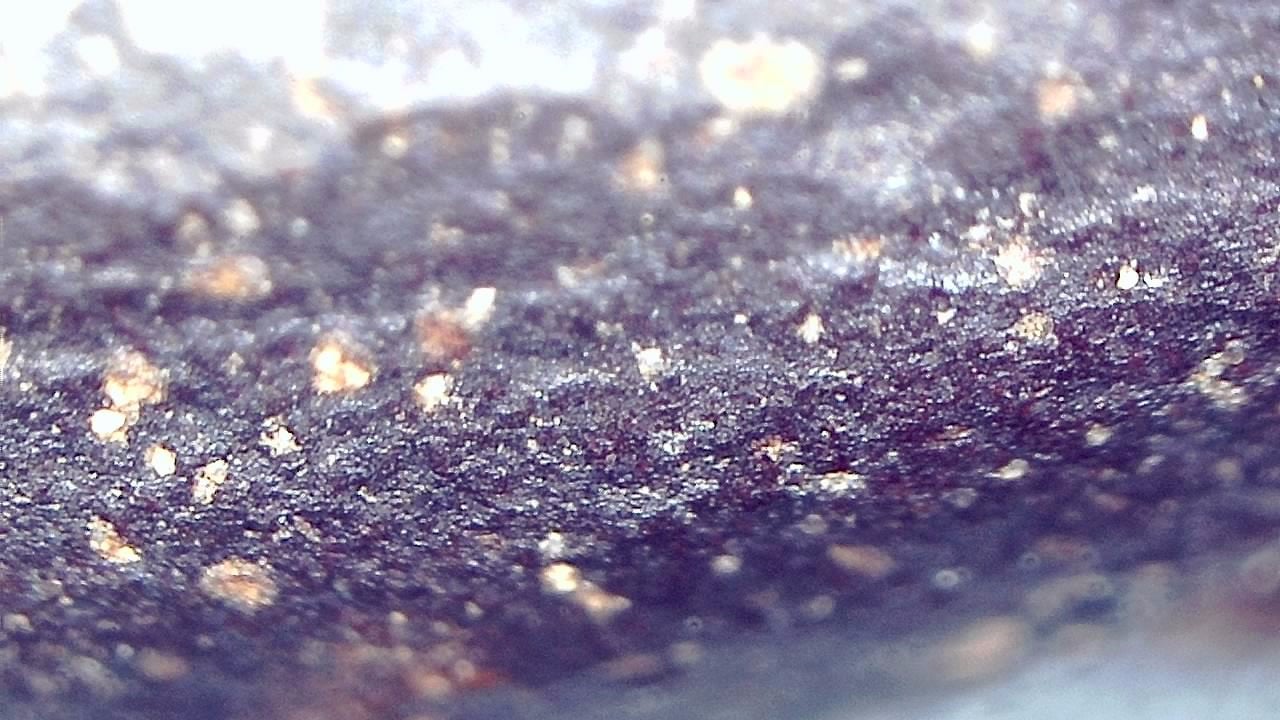

Raw material inspection

Detect visible defects, surface contaminants, or irregularities in ingredients and materials.

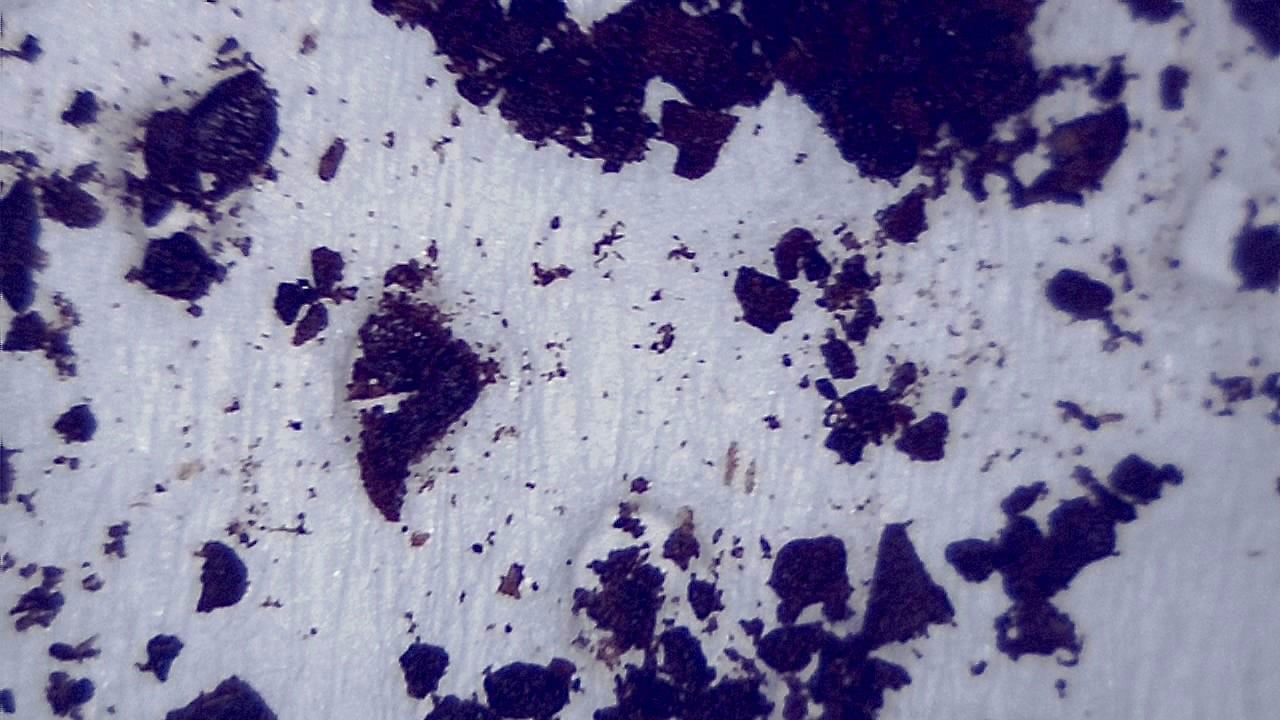

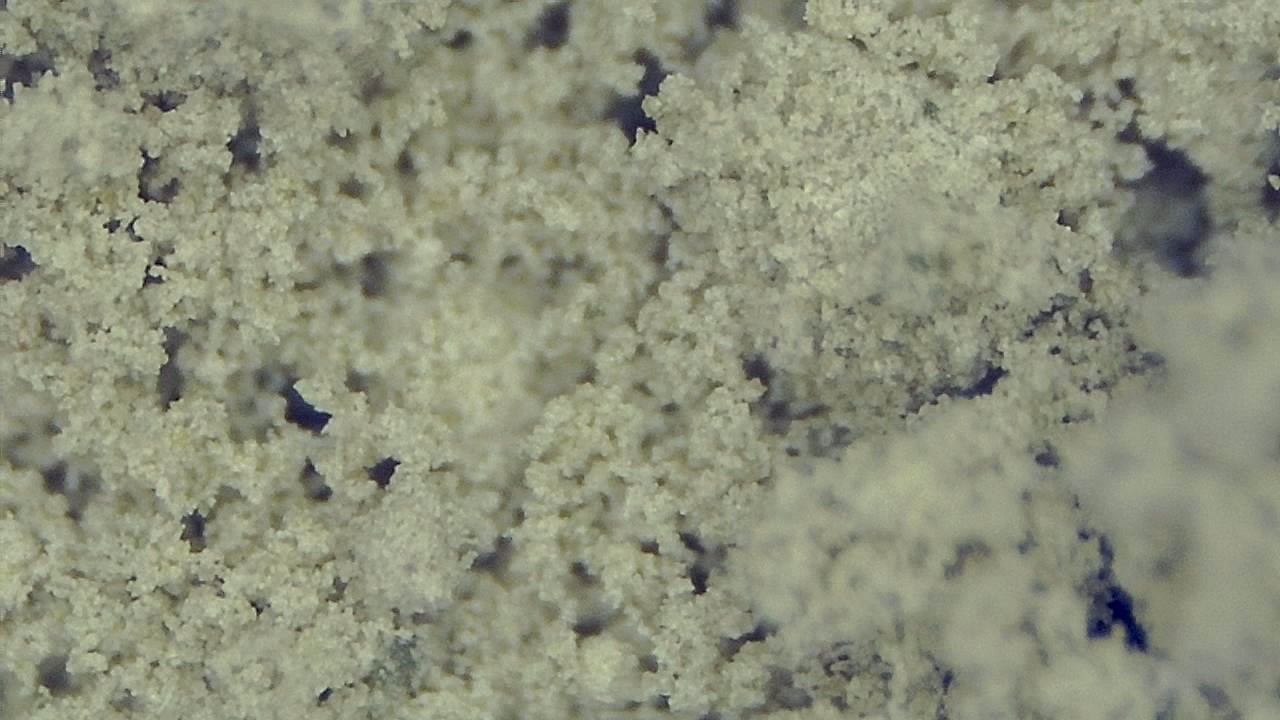

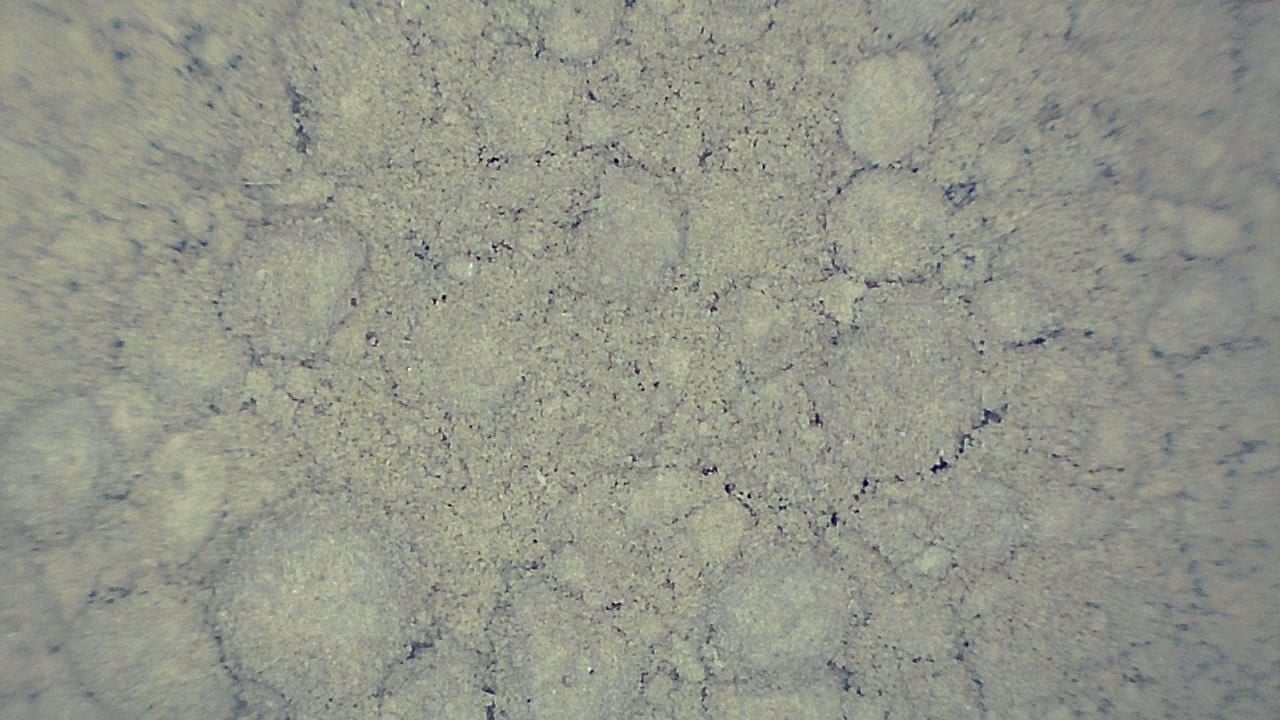

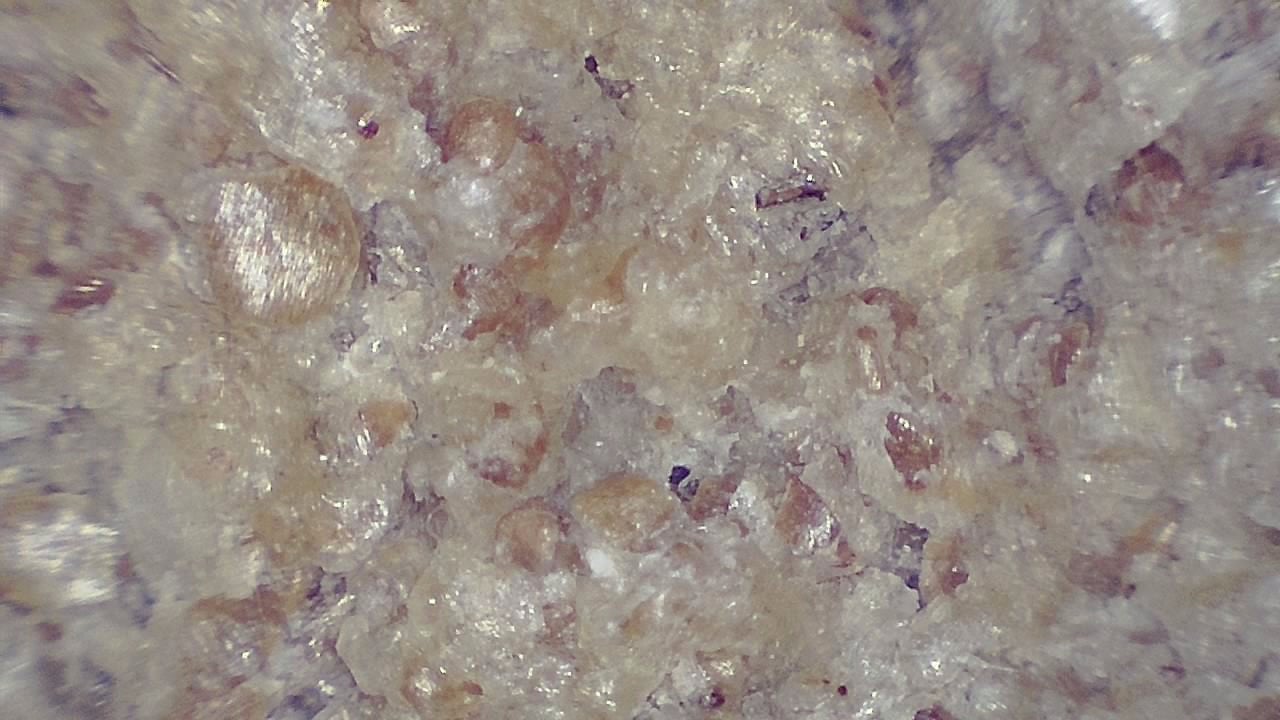

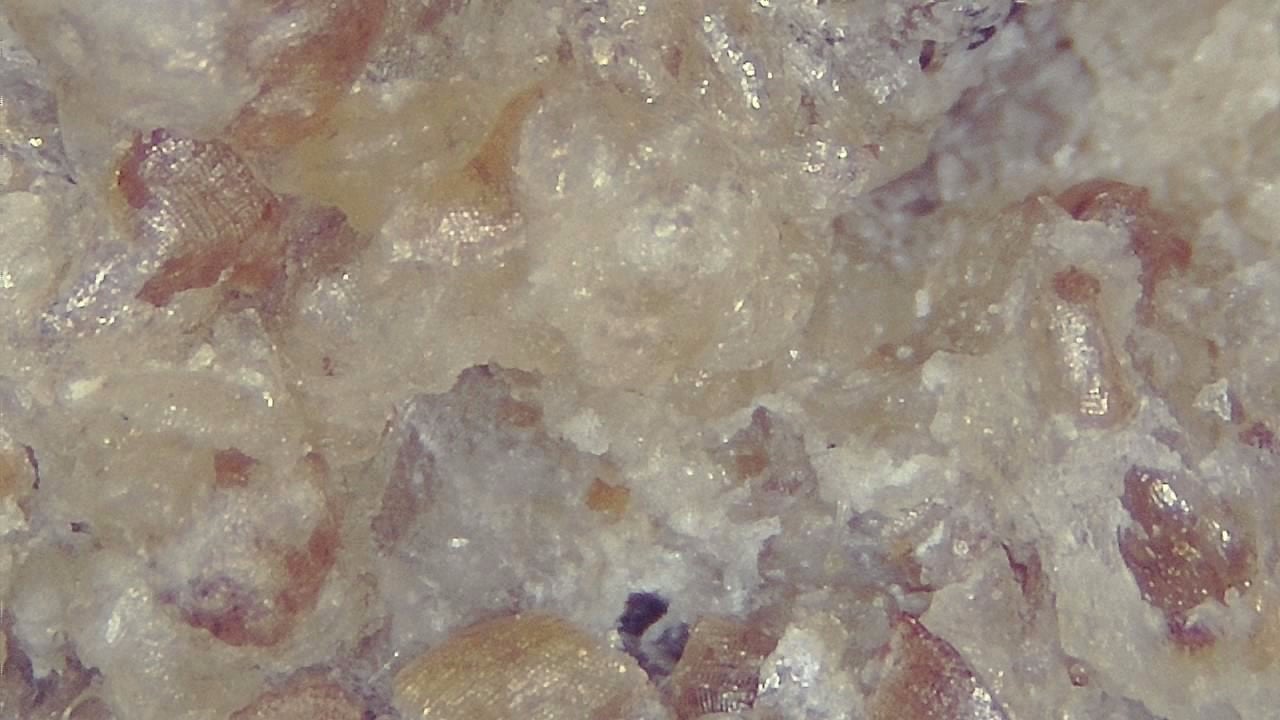

Final product visual control

Verify texture and surface finish in products where visual detail matters.

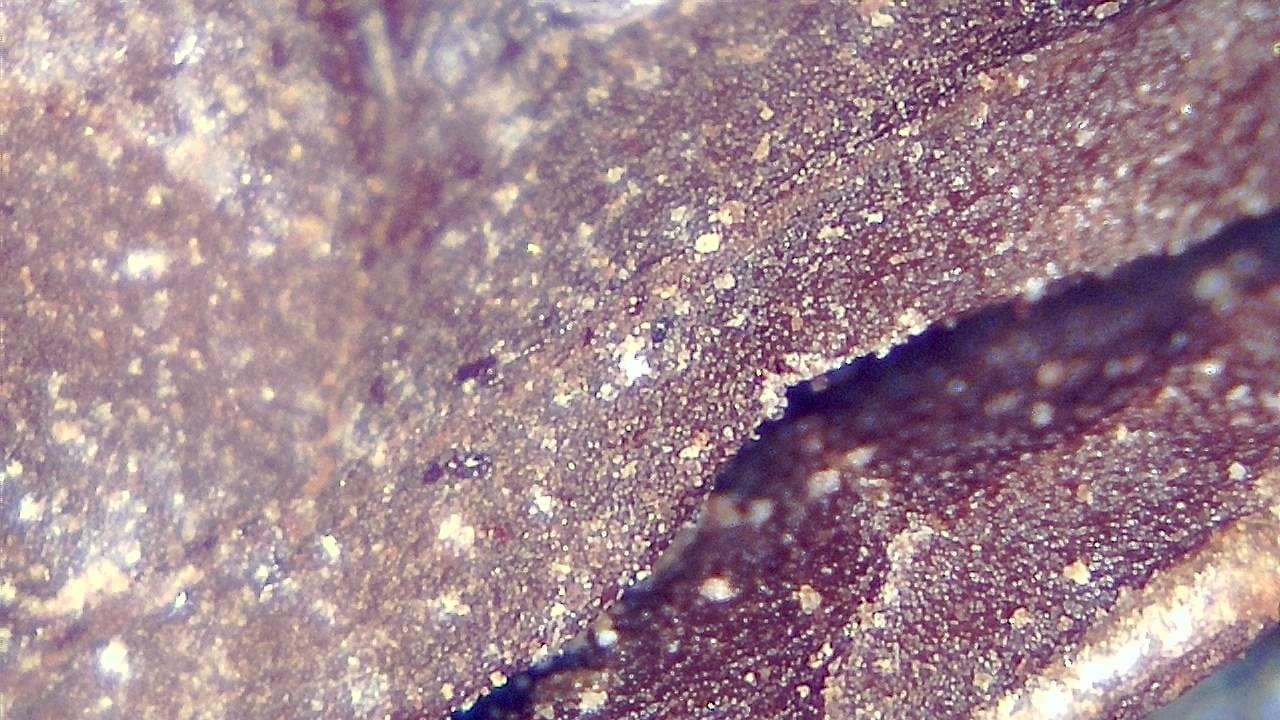

Incident documentation

Capture evidence for reports, audits, and supplier communication.

Limitations & best practices

- It is not a microbiological analysis system: bacteria/viruses require specialized lab techniques.

- Proper hygiene and handling protocols are required for food environments.

Interested in this use case?

Buy Smart G-Scope

Get the right kit for this application. Secure checkout and fast shipping.

Need help choosing? Tell us your workflow and we’ll recommend the best setup.

Related use cases

Electronics/PCB

Inspection of solder joints, components, and defects on printed circuit boards.

3D Printing

Surface quality control, layer defect detection, and material assessment for 3D-printed parts.

Jewelry/Watchmaking

Inspection of gemstones, settings, watch mechanisms, fine metalwork, and collectible coins for authentication and condition assessment.

Quality Control

Fast, accurate inspection of surfaces, parts, and assemblies to catch defects before they reach the customer.

Printing

Evaluate halftones, color registration, and print defects in detail for quality control in printing and packaging.

Cosmetics

Visual inspection of textures, particles, and impurities for quality control and product development.

Textiles

Detect defects in fibers, weaves, and finishes for textile quality control.