3D Printing Inspection

Surface quality control, layer defect detection, and material assessment for 3D-printed parts.

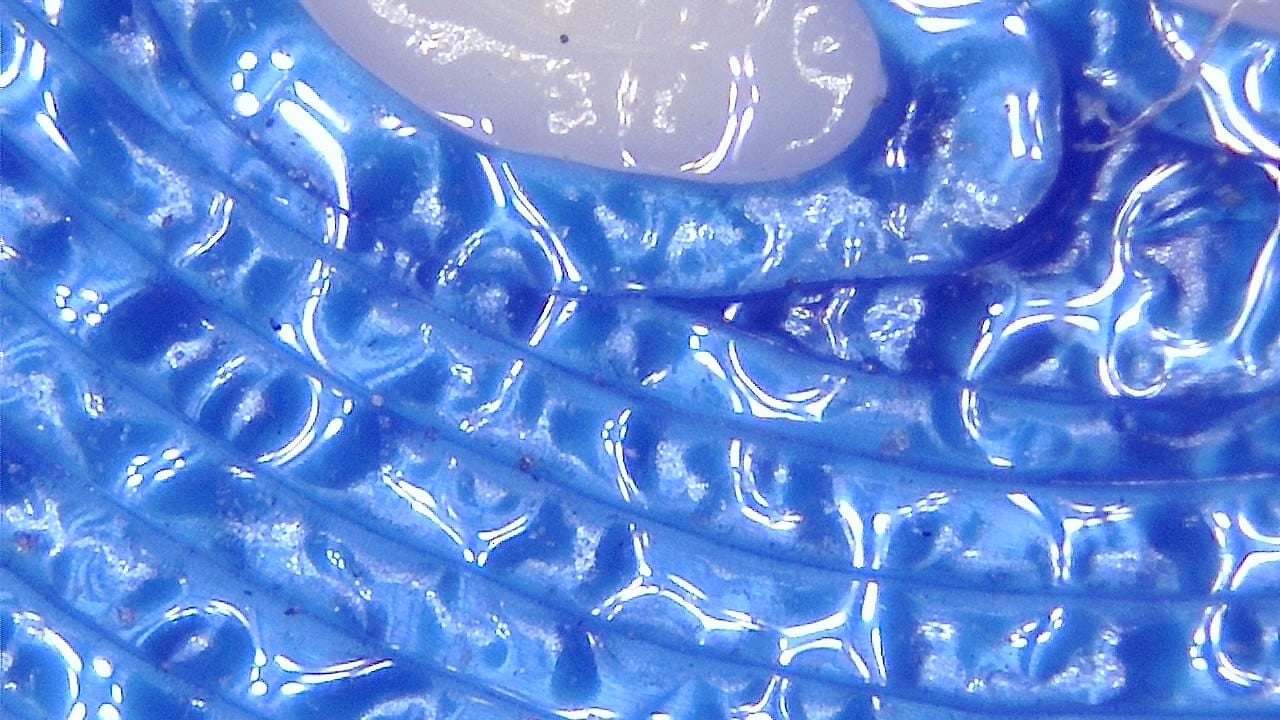

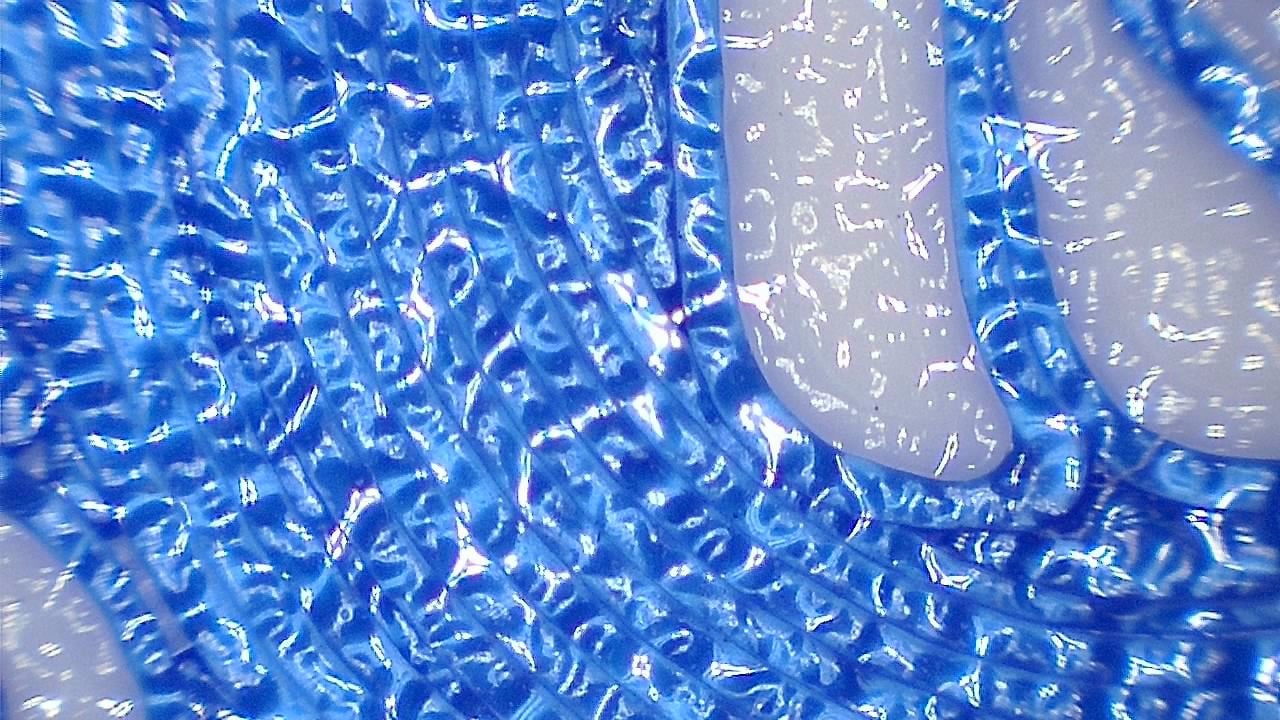

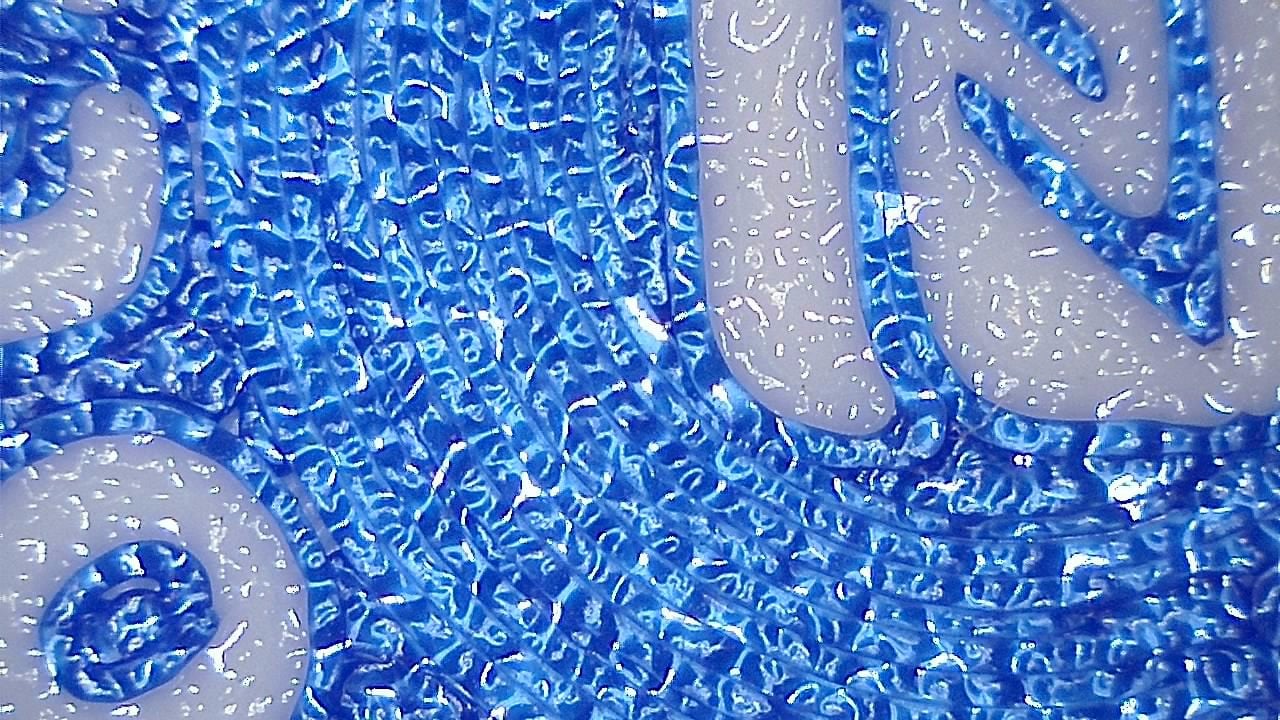

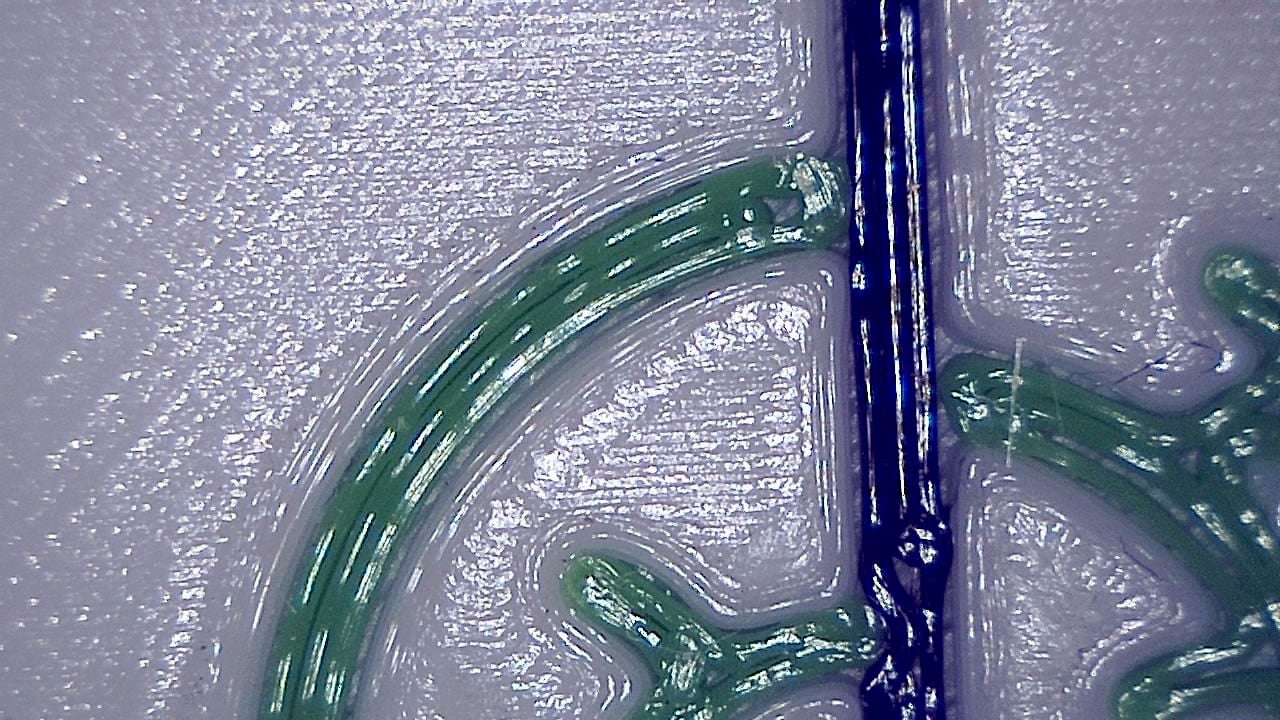

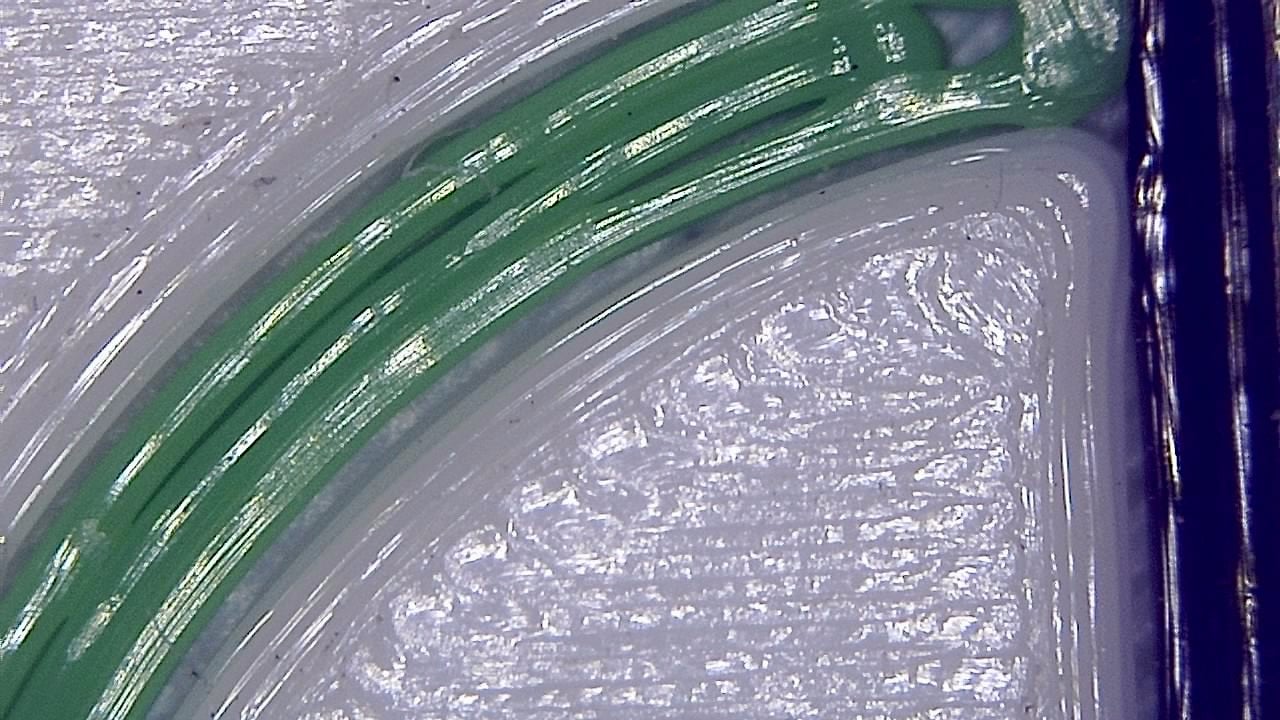

Both FDM and resin 3D printing present quality-control challenges that benefit from detailed visual inspection. Smart G-Scope helps examine layer quality and detect adhesion issues, bubbles, deformation, and contamination in printed parts.

For prototype makers and serial production, documenting and comparing surface quality across batches or print settings is essential to optimize processes and meet customer specifications.

It is also useful for assessing composite materials and additive filaments, checking particle distribution and mix homogeneity.

Key benefits

- Inspection of layer quality and surface finish

- Detection of bubbles, delamination, and warping

- Comparison of printing parameters

- Verification of composite materials and additives

- Documentation for QC and customers

Practical examples

FDM parameter optimization

A professional maker compares samples printed with different temperatures and speeds. Smart G-Scope images reveal the optimal settings that minimize visible layer lines and improve strength.

Quality control in dental production

A dental lab producing resin surgical guides uses the microscope to verify edge precision and absence of defects before delivering each piece to the dentist.

Limitations & best practices

- Internal structural analysis requires other techniques (CT, mechanical testing).

- Clean resin parts from residues before inspection.

- Consider material transparency/opacity when adjusting illumination.

Interested in this use case?

Buy Smart G-Scope

Get the right kit for this application. Secure checkout and fast shipping.

Need help choosing? Tell us your workflow and we’ll recommend the best setup.

Related use cases

Electronics/PCB

Inspection of solder joints, components, and defects on printed circuit boards.

Jewelry/Watchmaking

Inspection of gemstones, settings, watch mechanisms, fine metalwork, and collectible coins for authentication and condition assessment.

Quality Control

Fast, accurate inspection of surfaces, parts, and assemblies to catch defects before they reach the customer.

Printing

Evaluate halftones, color registration, and print defects in detail for quality control in printing and packaging.

Food

Supports visual quality control of foods and raw materials through fast inspection and documentation.

Cosmetics

Visual inspection of textures, particles, and impurities for quality control and product development.

Textiles

Detect defects in fibers, weaves, and finishes for textile quality control.